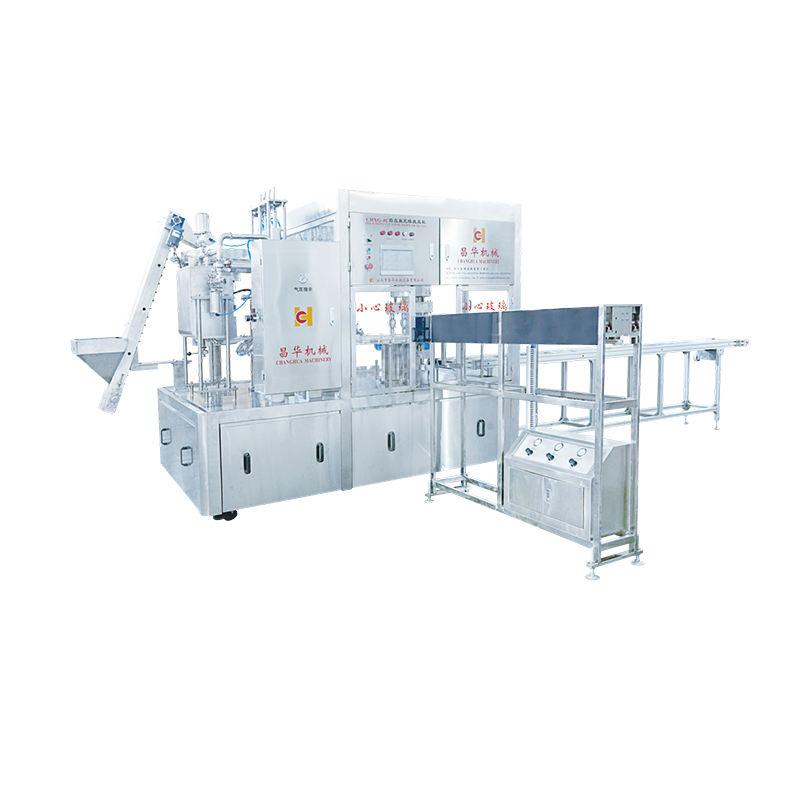

Coffee Bag Filling And Capping Production Line

Product Video

Product Description

Description of materials and structure for the entire machine:

① The frame is constructed with welded square tubes of SUS304 # stainless steel.

② The material contact parts are made of 304 # stainless steel.

③ The control cabinet and filling parts are designed separately for more convenient cleaning.

④ The rotating disc is made of aluminum alloy and covered with stainless sheet metal.

⑤ Equipped with a CIP cleaning system that utilizes a one-button start control method, the cleaning time is adjustable by the user and completed with sound and light prompts. It can clean the inner walls of the material container, filling valve, filling pipeline, and filling pump body.

*Work flow: automatic bag feeding→automatic bag free detection→manual bag hanging→automatic quantitative filling→automatic nitrogen filling (blowing) →automatic cleaning suction nozzle→automatic cap sort out→automatic cap-falling→cap-falling detection→automatic cap-turning (using permanent magnetic force to control torque)→automatic bag withdrawing→parallel transport. Except for manual bag hanging, the whole process is fully automatic control.

Product parameters

| Model | CHXG-4C |

| Production rate | 2800-3600 bags/H |

| Filling Volume | 250-550ml |

| Machine Power | 3-phase 4-lines/380V/50/Hz |

| Air Consumption | 0.7 m³/min 0.5-0.8Mpa |

| Machine Dimension | 3330x2900x2350mm(L x W x H) |

*Automatic cover feeder and finished product conveyor are optional equipment for customers. Customers can purchase according to the actual production demand to achieve more automatic and efficient production.

*We can design new models according to users' needs.

FAQ

What is the cost of this equipment?

The price will depend on your company's technical requirements for the equipment, such as whether you prefer to use domestic or foreign brands for related accessories and whether other devices or production lines need to be matched. We will provide accurate plans and quotations based on the product information and technical requirements you provide.

What is the estimated delivery time?

The delivery time for a single device is usually around 40 days, while large-scale production lines may require 90 days or more. The delivery date will be based on mutual order confirmation and the receipt of the deposit for your products and equipment. If your company requires earlier delivery, we will do our best to accommodate your request and deliver the equipment as soon as possible.

What are the payment options?

The specific remittance method will be agreed upon by both parties. A 40% deposit is required, with the remaining 60% payment due upon pickup.