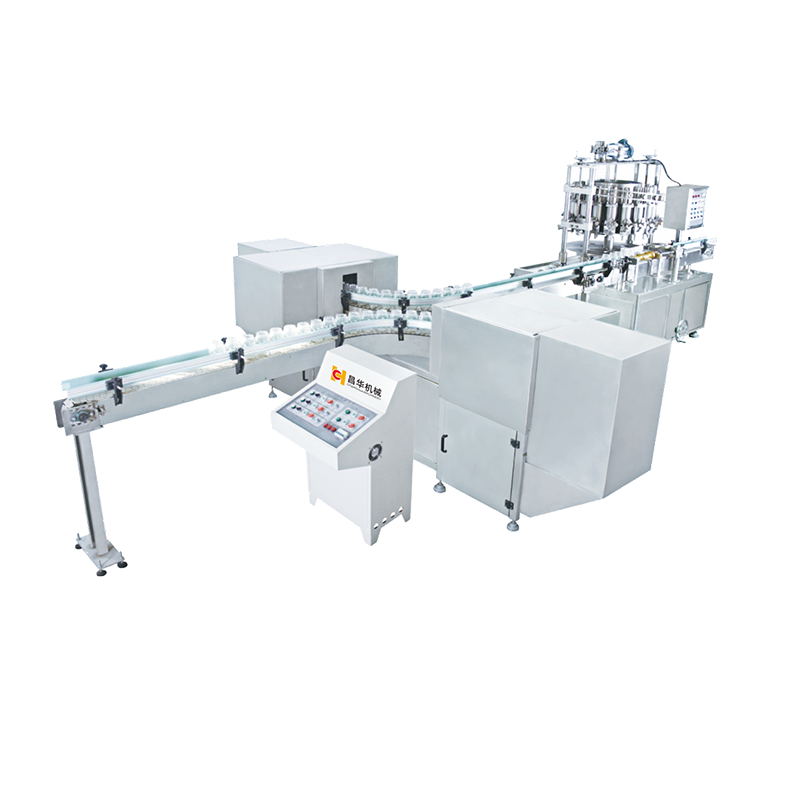

Automatic Bottle Washing And Filling Production Line

Product Description

*Material and structural description of the entire machine:

① This machine consists of four parts, namely the bottle feeding conveyor belt, the bottle washing and drying machine, the bottle discharging conveyor belt, and the filling machine.

② Easy to operate, easy to maintain, simple adjustment between bottle types, no need to replace parts, and low bottle breakage rate and low water consumption. The speed adopts German Siemens variable frequency speed regulation. It is an ideal supporting equipment for production lines in the food industry such as alcohol, beverages, and canned goods.

*Work flow: Bottle Entry → Bottle Washing → Air Drying → Bottle Exit → Filling.

Product parameters

| Production rate | 4800-8000 bottles/H |

| Adaptation bottleneck | Ø50--120mm |

| Adapt to bottle height | 80--220mm |

| Spray pressure | 0.3--0.5Mpa |

| Jet pressure | 0.3--0.5Mpa |

| Machine Power | 3-phase 4-lines/380V/50/Hz |

*We can design new models according to users' needs.

FAQ

1.What is the price of this device?

It depends on your company's technical requirements for the equipment, such as using domestic or foreign brands for related accessories, and whether other devices or production lines need to be matched. We will make accurate plans and quotations based on the product information and technical requirements you provide.

2. How long is the delivery time approximately?

The delivery time for a single device is generally 40 days, while large-scale production lines require 90 days or more; The delivery date is based on the confirmation of the order by both parties and the date we receive the deposit for your products and equipment. If your company requires us to deliver a few days in advance, we will do our best to meet your requirements and complete the delivery as soon as possible.

3. Payment method?

The specific remittance method shall be agreed upon by both parties. 40% deposit, 60% pick-up payment.